Product Category

We have wide

Variations of Products

Jai Auto's products are manufactured using the latest equipment and technology in a well-equipped plant that adheres to the international manufacturing quality standards.

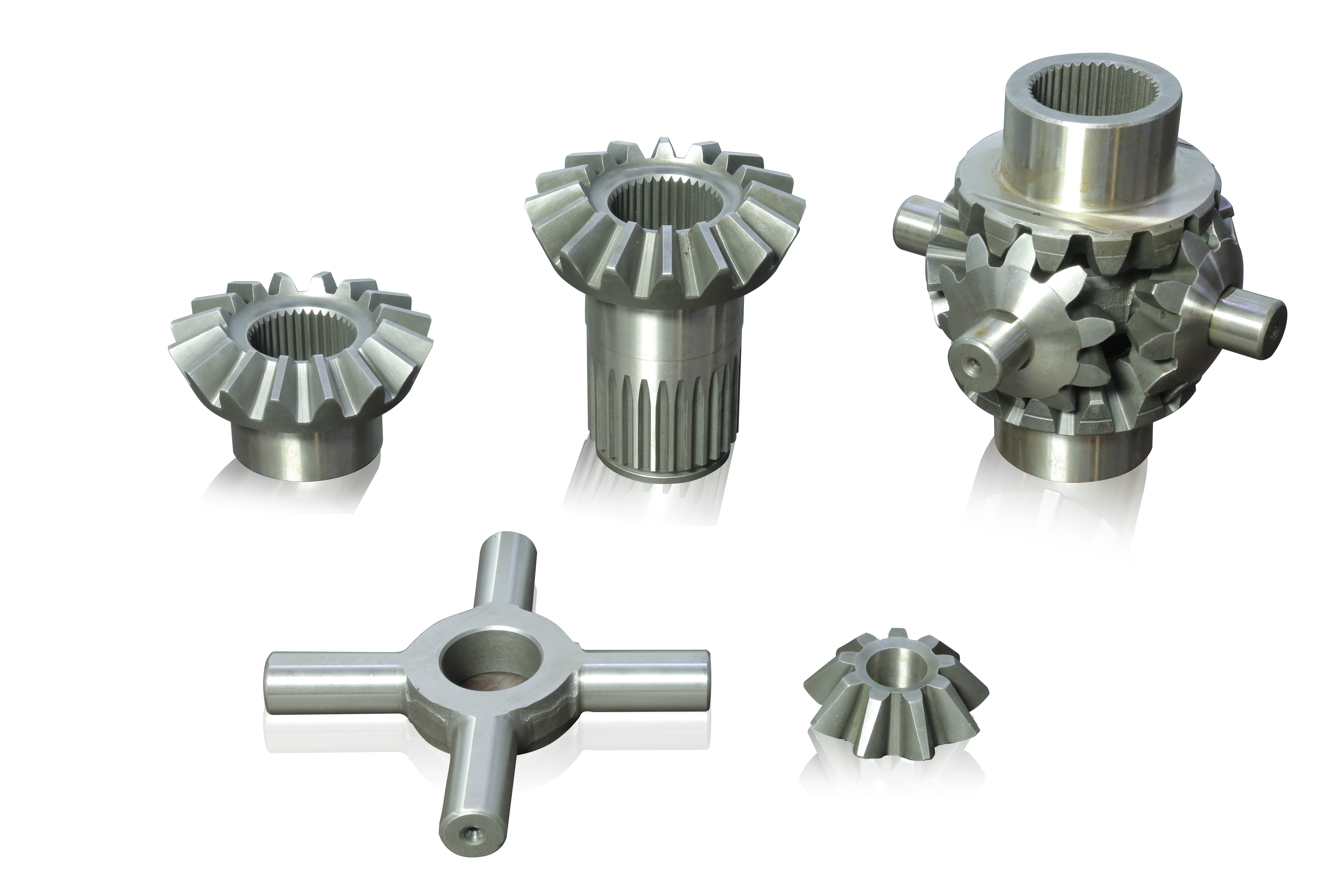

Differential Bevel Gear

Innovative leadership and enduring product reliability is achieved based on extensive knowledge acquired over years in the Automotive Industry. With expertise in Diverse Technology using CAD, CNC Machining and avante-garde Inspection and Quality Control Equipment, JAPL offers quality products of a range of Differential Bevel Gears for all types of heavy and light Commercial Vehicles, Agricultural Tractors, Cars and Earth Moving Equipments.

Jai Auto is a leading manufacturer of gears for light commercial vehicles such as Toyota, HINO, GM, Ford, Chrysler, Chevrolet and Dana Axles.

In Heavy Commercial vehicles, the vehicles covered are Mercedez Benz, Scania, Volvo, HINO, Fuso and Nissan.

Amongst the Agricultural Tractor Parts range include parts for Massey Ferguson, Ford, New Holland, Fiat, UTB, IMR, URSUS and VALTRA. Our products range for all the above applications is indicative of our strength in manufacturing capability.

Enquiry Now

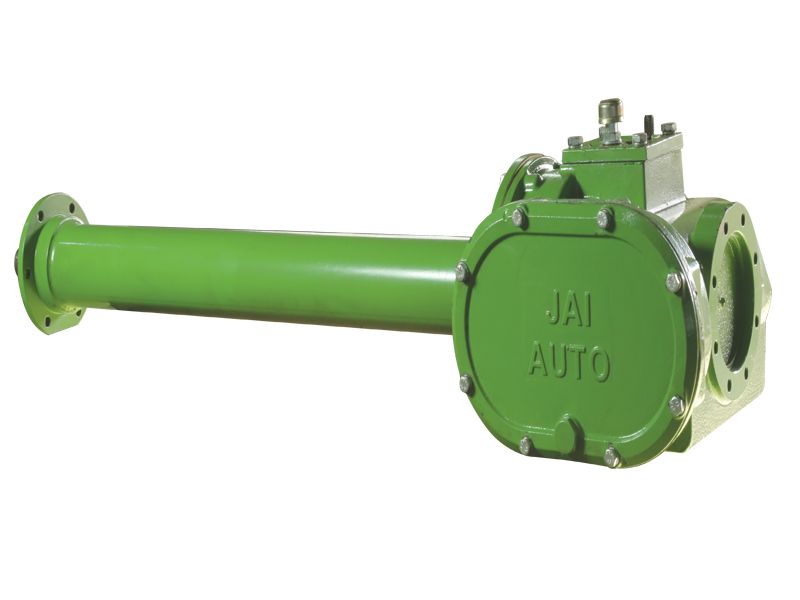

Gearboxes For Agricultural Implements

We are Industry's top designer & manufacturers of Agricultural Gear Boxes

Enquiry Now

Forging & Flanges

Jai Auto's product range of different types of Flanges being manufactured are detailed below with the details of the materials used with their specifications:

Enquiry Now

Internal Ring Gears (Power Skived)

Ring Gears – Jai Auto Pvt. Ltd.

Jai Auto Pvt. Ltd. offers precision-engineered Ring Gears manufactured to meet the stringent requirements of global OEMs and Tier-1 suppliers. Our dedicated ring gear production line is supported by fully in-house forging and ring rolling facilities, ensuring superior metallurgical control and dimensional accuracy.

We specialize in the manufacture of internal tooth ring gears using advanced gear manufacturing technologies such as Profilator power skiving, skiving, gear shaping, and broaching processes. Heat treatment is carried out in-house through CGCF and SQF furnaces for carburising and carbonitriding, followed by Gleason press quenching to achieve optimal hardness and durability.

To meet diverse application needs, we also provide in-house induction hardening, delivering consistent performance, wear resistance, and extended service life.

Manufacturing Capability:

Ring Gear Diameter Range: 50 mm to 500 mm

Our integrated manufacturing approach ensures high precision, consistent quality, and reliable performance for automotive, transmission, and industrial applications.

Enquiry Now

.JPG)