Quality Assurance

Our quality control system, developed over the years, is implemented right from the inspection of raw material to the final dispatch. Our testing lab is equipped with the necessary measurement and testing tools to enable stage-wise product testing while being put through the manufacturing process. Our priority is to achieve highest level of customer satisfaction by delivering quality products and services to our valued customers for now and forever. Jai Auto has strong technology and human resources base to meet the exacting standards of the most demanding customers in India & Globally. We use branded instruments to measure & calibrate it regularly. In order to maintain quality in high volume environment, robust quality plans with checks and controls at multiple layers are established to ensure zero defect products to Customers. We actively promote our quality policy and ensure consistency and visibility of quality standards, processes and performance indicators across all level at Jai Auto Pvt. Ltd. Our priority is to achieve highest level of customer satisfaction by delivering quality products and services to our valued customers for now and forever. The raw material is fully inspected dimensionally and metallurgical.

Raw Material:

Forgings are procured using steel from approved steel mills only. Forgings are received Heat Code Wise in duly Isothermally Annealed/ Normalized condition. Following Checks are carried out before further processing:

- Visual Inspection for cracks and folds

- Dimensional Inspection

- Check of Chemical Composition by spectro Analysis

- Hardness

- Jominy hardenability

- Micro Structure and Inclusions

- Grains size and Grain Flow

In Process:

- First off inspection

- Patrol Inspection at defined interval as per control plan

- For Bevel Gears check tooth contact in soft gears

- Before Heat treatment Inspection for all parts

- For Bevel Gears Final Testing to ensure back-lash at correct mounting distance, tooth contact, run out and marking mounting distance variations.

Heat Treatment:

- Batches are subjected to checks on

- Effective Case Depth

- Core and Surface Hardness

- Microstructure- Case and core

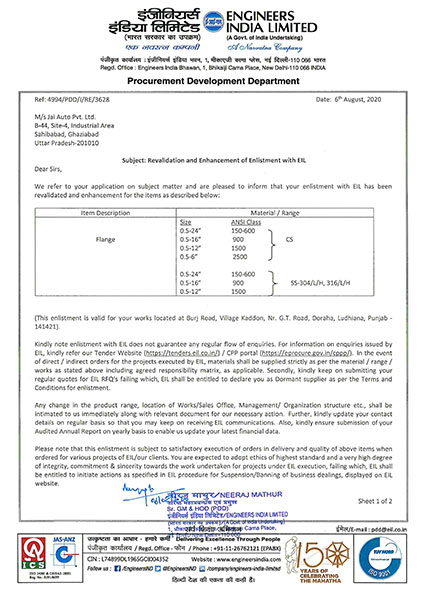

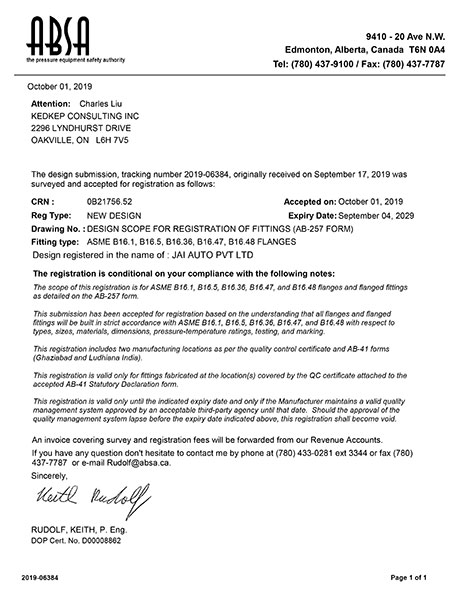

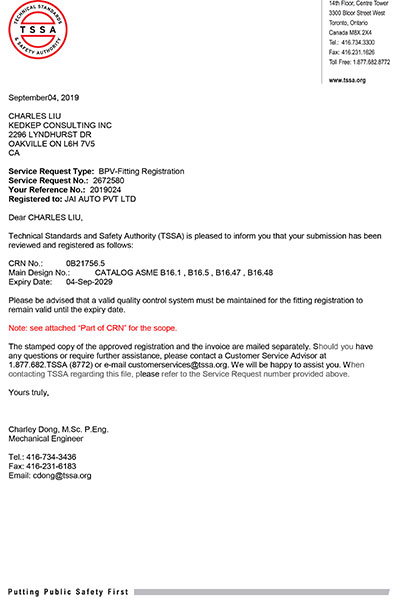

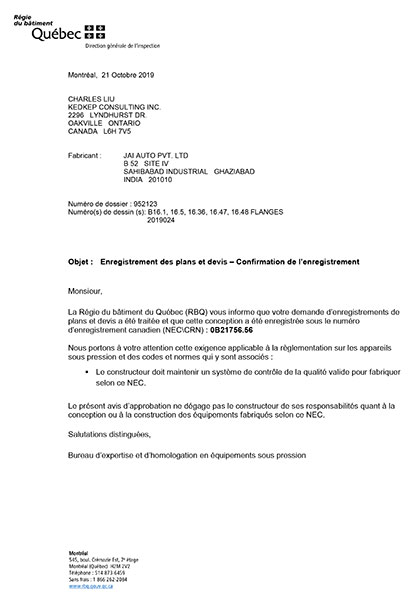

.jpg)

.jpg)

.jpg)

-(01-10-2020)-(1).jpg)

.jpg)

.jpg)

.jpg)

-(01-10-2020)-(1).jpg)

(1366 x 300 px) (1).png)